Our premium 100H roller chain sets the bar for performance, durability, and strength! This chain has a 1.250" (1-1/4") pitch and dimensionally conforms to ANSI B29.1 dimensional standards. What sets this 100H heavy roller chain apart from others besides the "premium" branding is; solid bushings & rollers, specially hardened pins, wide-waste side plates, shot peened components, factory pre-loading, and a high-quality factory-applied lubricant. Solid bushings and rollers improve the chains' life and performance while also creating superior contact with the root of the sprocket teeth, improving the sprocket's life. The importance of a perfectly cylindrical round part in a roller chain is often overlooked! When it comes to strength, the pins play a vital role. Interestingly enough, most chain failures occur from pin breakage; using specific heat treatments and hardened techniques, our premium 100H heavy roller chain pins are superior to the "standard" and can withstand higher loads. Pairing that with the unique wide-waste side plates created a 100H chain more powerful than its predecessor. The processes of shot-peening components and factory pre-loading the chain improve fatigue capabilities and stretch! Post-manufacturing, a high-quality chain lubricant is applied on all chain surfaces (including internally) for enhanced performance. For additional information or to get a quote, contact our customer service team, and we will be happy to assist you!

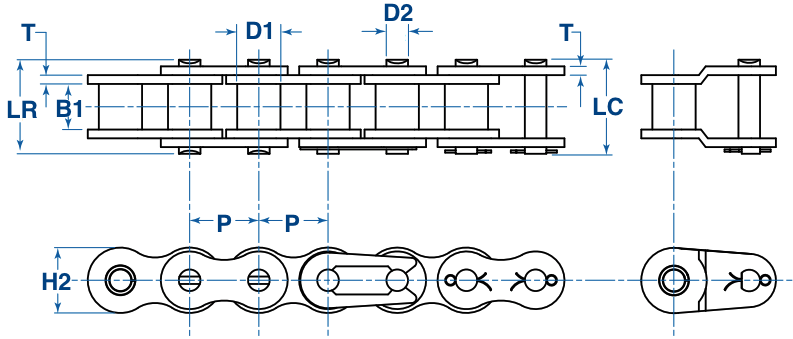

100H Roller Chain Dimensions

- Part #: 100H

- Pitch (P): 1.250"

- Roller Diameter (D1): 0.750"

- Width Between Inner Plates (B1): 0.750"

- Pin Diameter (D2): 0.375"

- Overall Chain Width (LR): 1.75"

- Overall Connecting Link Width (LC): 1.98"

- Plate Height (H2): 1.18"

- Plate Thickness (T): 0.187"

- Average Tensile Strength: 29,000 LBS

- Rated Working Load: 6,360 LBS

- Weight Per Foot: 3.0 LBS

100H Heavy Chain Difference

The thicker side plates are what separates a 100H heavy roller chain from a standard 100 chain. The additional material increases the chain's wear life, strength, and shock load capabilities. Additionally, the 100H chain will operate on standard sprockets. One important note to factor in, though, is if you are changing your application from 100 chain to 100H heavy chain, it is imperative to ensure that your current application has an appropriate amount of clearance available due to the overall width of 100H chain being greater than a standard 100 chain.

Premium 100H Chain Benefits

|

High-strength heat-treated solid rollers to keep the cylindrical shape of the roller long term and for optimal chain performance.

|

|

Compared to the standard split-bushing design, cold-forged solid bushings are made to precise roundness for greater strength and performance.

|

|

Heat-treated parts (including pins) for added strength and surface hardness, resulting in a longer working life.

|

|

Shot Peened Parts to alleviate stress concentrations and increase strength.

|

|

Wide-Waste Side-Plates for added fatigue resistance and reduction in progressive elongation.

|

|

Factory Preloading is the final process that greatly reduces stretch and ensures all components are properly aligned.

|