V-Guide Wheel Roller Bearings

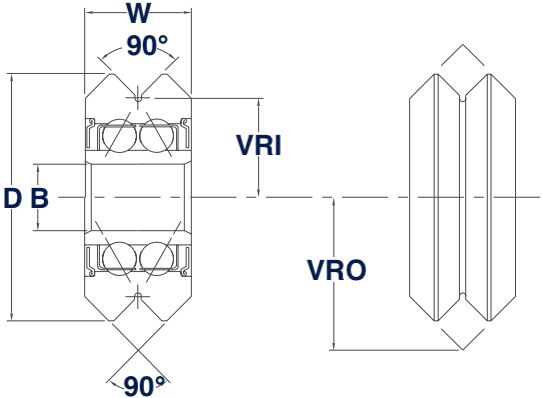

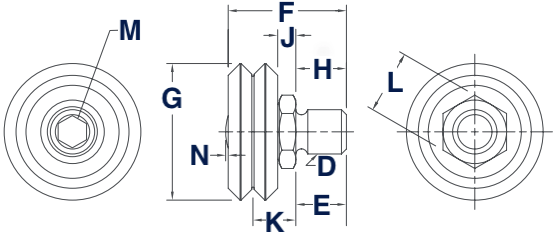

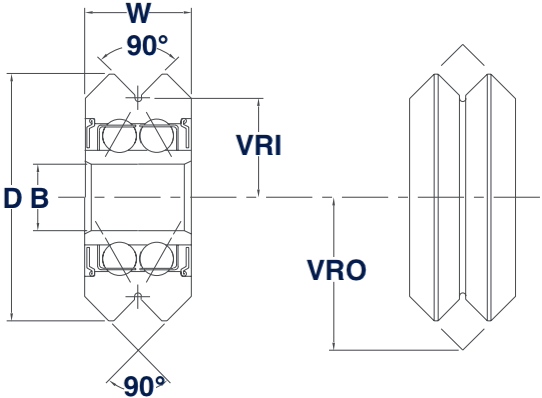

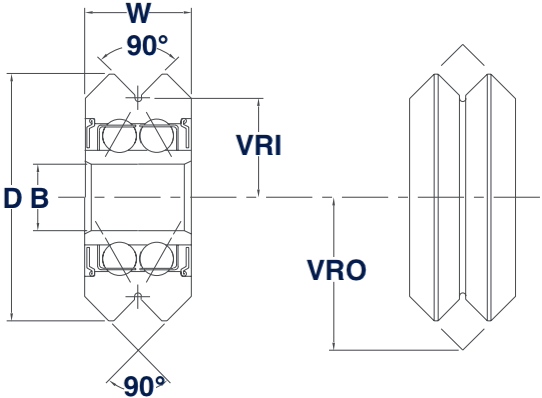

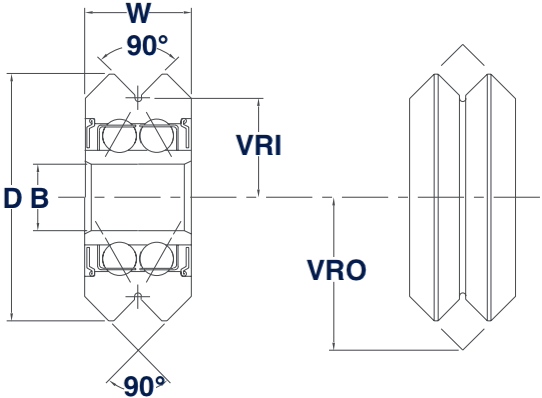

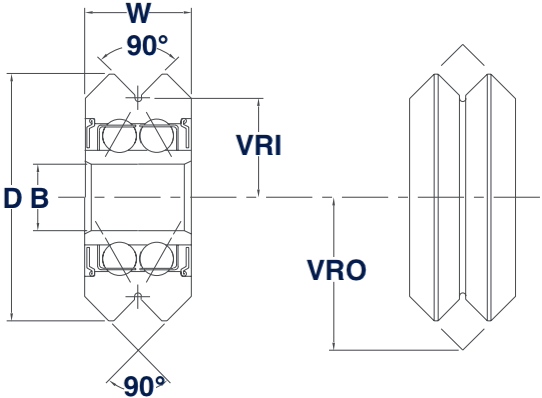

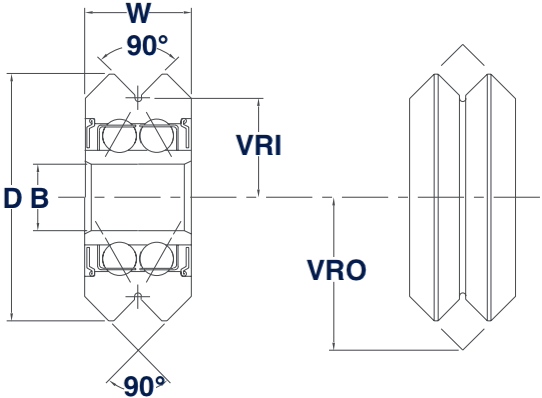

V-groove guide wheel bearings are utilized in a range of linear and rotary motion applications. These bearings provide a low-noise, low friction, smooth, and long-lasting solution for linear movement systems. V-guide wheel roller bearings utilize precision tracks and accessories for optimal operation with minimal energy consumption. The 90° dual-vee design allows for a natural whipping action, clearing debris and optimally functioning the system. We offer these bearings in a wide range of configurations and materials to suit almost any application. Utilizing a dual-vee bearing system creates an easy to maintain and economical method for movement. We also stock and supply all of the different track configurations, bushings, covers, and more! For additional information or to get a quote on v-guide wheel roller bearings, contact our customer support team, and we will be happy to assist you!

V-Guide Wheel Roller Bearing Types

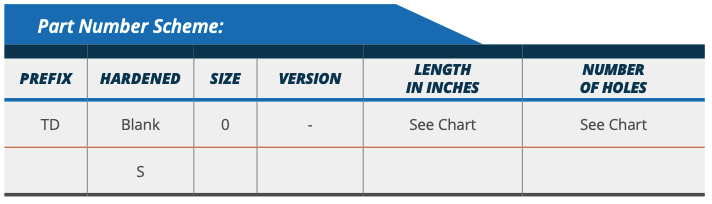

Note:

The below chart shows the standard options for dualVee bearings; we also supply custom solutions upon request.

V-Guide Wheel Roller Bearing Information

V-Groove Guide Wheel Sizes

The below charts show standard stock sizes in each configuration, for custom bearings please contact us.

The original guide wheels are designated with W_ and W_X for the part numbers. W_ part numbers are Shielded, and W_X part numbers are Sealed/ Shielded.

Stainless steel original guide wheels are made for corrosive conditions and are commonly found in medical, scientific, food, and beverage applications; the wheel bearing is made from 440C stainless steel, and the retainers are made from nylon 6,6.

Studded polymer wheels are utilized in corrosive environments or applications requiring low noise bearings. Some of these applications include electronics, scientific equipment, and medical applications.

Vacuum wheels are made for vacuum environments and are typically found in material science applications.

Washdown V-Guide bearing wheels are made from high-quality 440C stainless steel and have Nylon ball retainers. These wheels are made for washdown equipment, food processing, and pharmaceutical equipment.

These v-guide wheel bearings are food grade and pharisaical grade; they are utilized in good and pharma processing and handling equipment.

Extreme temperature wheels are made for high temp or low temp applications. Common applications include aerospace, refrigeration, baking, welding, and cutters.

High-Temperature Wheels: Low-Temperature Wheels:

Low-Temperature Wheels:

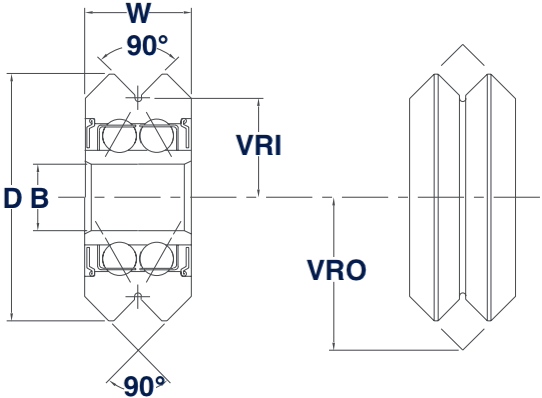

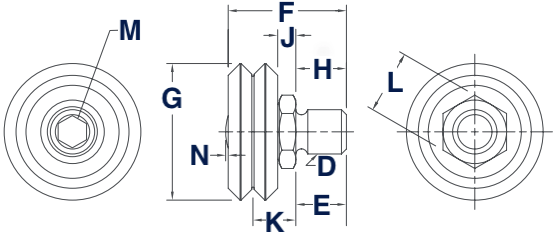

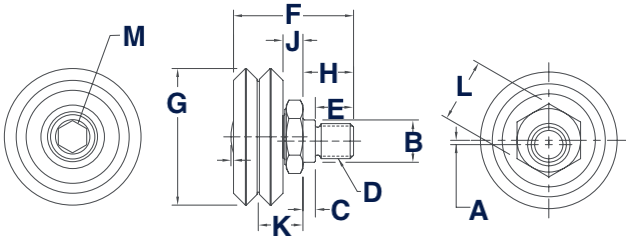

Concentric Studded Wheels With End Hex: Eccentric Studded Wheels With End Hex:

Eccentric Studded Wheels With End Hex:

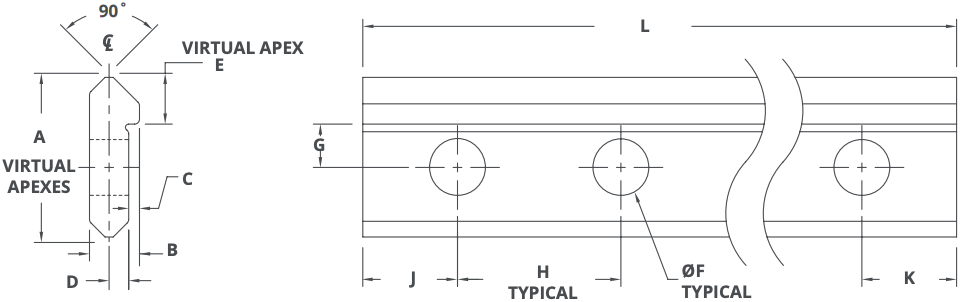

Tracks are designed and manufactured to precision tolerances to ensure a smooth operation with the bearing wheels.

Single-Edge Track Dimensions: Single-Edge Track Dimensions: Standard Lengths and Holes:

Notes:

Standard Lengths and Holes:

Notes:

- Tolerance for the shoulder to Hole (G) is +/- 0.005"

- Tolerance for hole spacing (H) are non-cumulative and +/- 0.005"

- Tolerance for hole end spacing 1 and 2 (j and K) is +/- 0.005"

- Tolerance for overall length (L) is +/- 0.015" with holes and +/- 0.063" when cut to length without holes.

- Carbon steel track material is AISI 1045, available soft at HRc 22-25, or induction hardened 0.01" deep to HRc 53 minimum.

- Stainless steel track material is AISI 420, available soft at HRc 20-22, or induction hardened 0.01" deep to HRc 40 minimum, contact us to discuss material options.

- Track finish is polished and oiled for corrosion resistance.

- Maximum single piece track lengths are 20 feet hardened, or 22 feet soft.

Track Lubricators utilize a premium white wool felt for dispursing light-weight synthetic oil onto the track, the felt holder is made from high-quality AISI 300 stainless steel as well as the mounting hardware.

Track Lubricator Sizes: Track Lubricator Sizes:

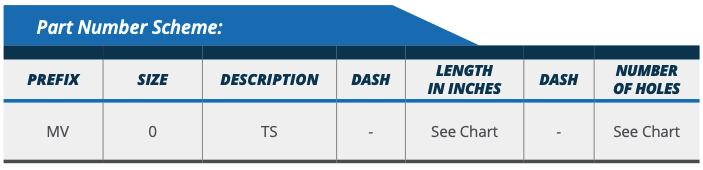

Minvee Linear Slide System

The Minvee linear slide systems made from Bishop-Wisecarver are miniature guides that consist of 1.75" wide by 2" long wheel plates that utilize AISI 52100 carbon steel or polymer wheels and double vee-edge guide tracks. It's important to note that when used with available 6063-T6 aluminium track support extrusion, assembled height is 0.788". MinVee double-edge track is also available in AISI 1045 carbon steel in six standard lengths up to 36.5" with mounting holes predrilled. Axial working capacities are 121.4 lbf for steel wheels and 15 lbf for polymer wheel versions. The Minvee systems can be found in many applications such as; semiconductor, laboratory, and medical applications with compact space requirements.

MinVee Wheel Plates

Wheel plates consist of two concentric and two eccentric DualVee studded wheels with an anodized aluminium wheel plate that has a stainless steel lubricator housing and felt lubricator pads. The below chart shows the standard configuration options, but custom configurations are available upon request.

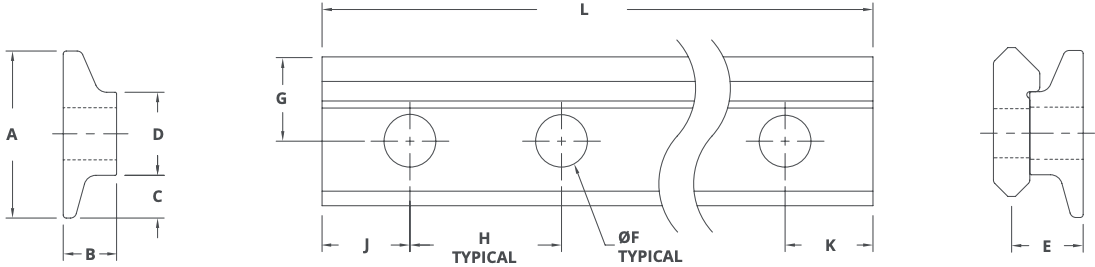

Double Edge MinVee Track:

These tracks are precision manufactured to accommodate the miniature nature of these linear systems.

- Tolerance for Shoulder to Hole (G) is +/-.005"

- Tolerance for Hole Spacing (H) are non-cumulative and is +/-.005"

- Tolerance for Hole End Spacing 1 & 2 (J & K) are: +/-.005"

- Tolerances for Overall Length (L) are +/-.015 [+/-.38] with holes, and +/-.063 [+/-1.60] when cut to length without holes.

- Track material is AISI 1045 carbon steel, available soft at HRc 22-25, or induction hardened 0.01” deep to HRc 53 minimum.

- Track finish is polished and oiled for corrosion resistance.

- Maximum single piece track lengths are 20 feet hardened, or 22 feet soft.

Dimensions:

Standard Lengths and Holes:

MinVee Track Support

- Tolerance for Shoulder to Hole (G) is +/-.005"

- Tolerance for Hole Spacing (H) are non-cumulative and is +/-.005"

- Tolerance for Hole End Spacing 1 & 2 (J & K) are: +/-.005"

- Tolerances for Overall Length (L) is +/-.063"

- Track support material is 6063-T6 aluminium with an anodized finish.

- Track support holes and cut to length ends are unfinished bare aluminium.

- The maximum single piece track length is 10 feet.

Dimensions:

Standard Lengths and Holes:

|

|