Sugar Mill Chains

It's no secret that sugar is the world's, favorite sweetener. To make sure that this crystal makes it from field to grocery store shelves USA Roller Chain and Sprockets sets itself apart from other mill suppliers by providing an unparalleled quality of service, field experience, and expertise. Supplying sugar mills within the Central and South Americas with quality products such as chains, sprockets, bearings, and custom solutions, we aim to be your power transmission partner instead of just a supplier.

.PNG) besides the chains themself, we also offer a wide range of other sugar mill products such as electric motors, bearings, sprockets, and conveyor belting.

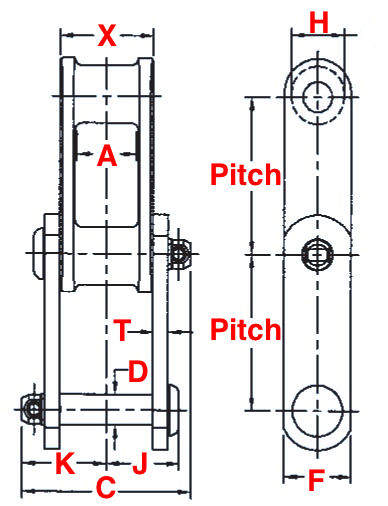

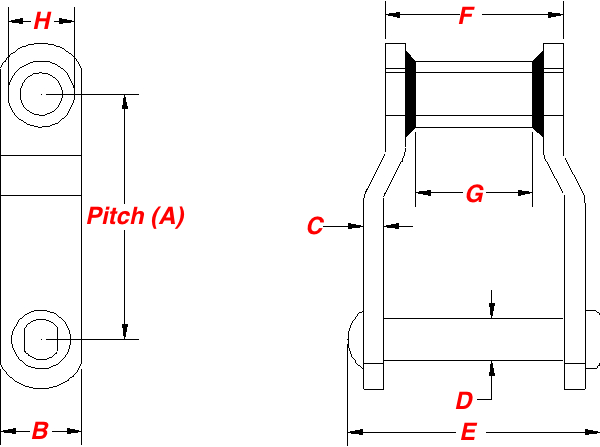

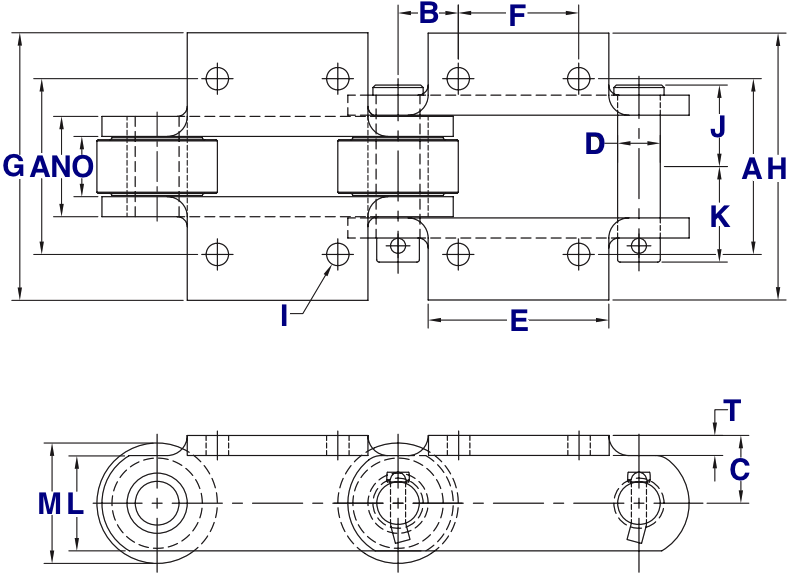

Cane feeder and wash tables within sugar mills will typically utilize steel bushed (SS) and cast combination Engineer Class chains due to their high-strength and elongated wear life nature of this specific type of chain in the application, also found in this application is welded steel chains and rivetless drop forged chains. Steel bushed chains utilize high-strength steel pins, bushings, rollers, and side-plates. While cast combination chains utilize steel outer side-plates and pins with a solid cast block link (inner link), the benefit of using a cast combination chain over steel bushed is that the cast block links have elliptical barrels that add material at the point of sprocket contact which extends the overall life of the chain. However, steel bushed (SS) chains offer higher tensile strengths than the combination chains. All steel parts on either option are optimally hardened and go through specific manufacturing processes at the factory to ensure optimal working life and performance for their individual task in the operation of the chain.

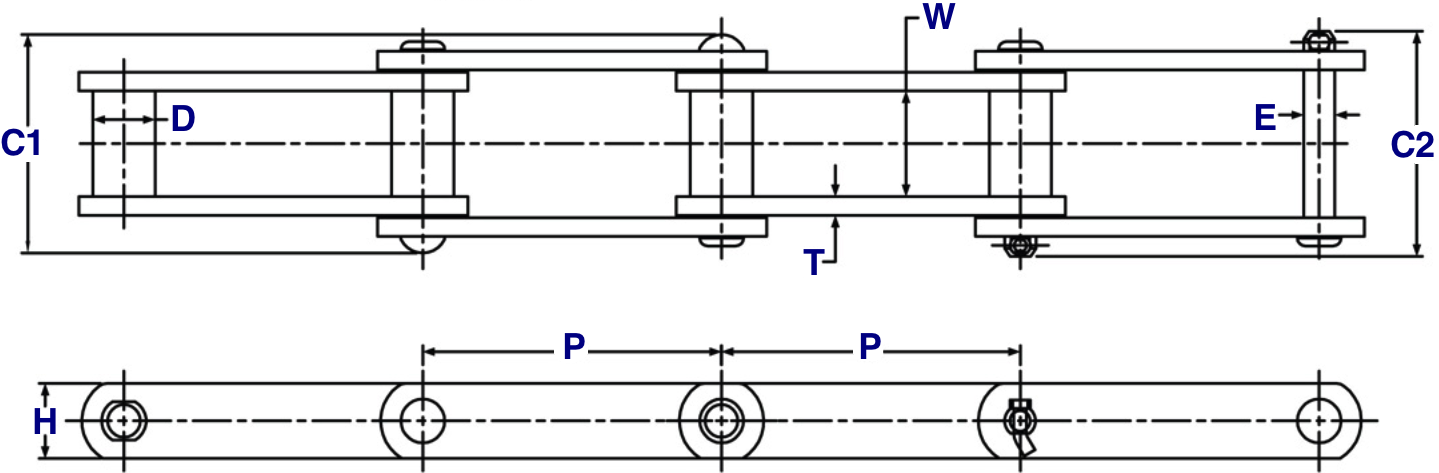

Steel Bushed Chain Sizes

S1 Attachments:

S1 Attachments:

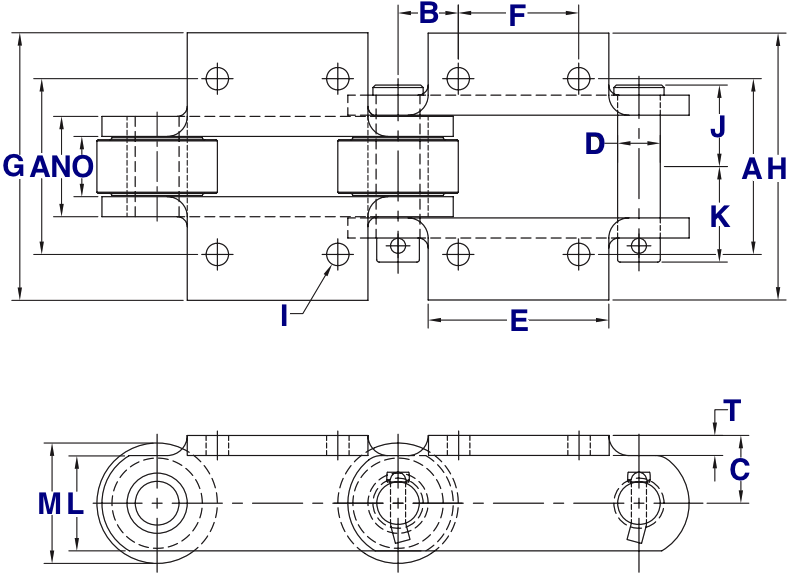

Cast Combination Chain Sizes

S1 Attachments:

S1 Attachments:

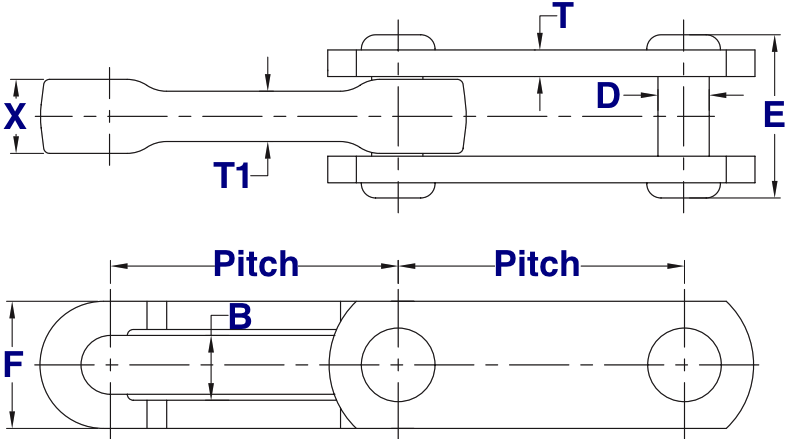

Welded Steel Chains

WR = standard WH = standard with all components heat-treated WR**HD = heavy-duty welded steel chain WH**HD = heavy-duty welded steel chain with all components heat-treated WR**XHD = extra heavy-duty welded steel chain WH**XHD = extra heavy-duty welded steel chain with all components heat-treated SS = stainless steel welded steel chain  Welded Steel S1 Attachment:

Welded Steel S1 Attachment:

Drop Forge Rivetless Chains

Drop forged rivetless chains and S-class bar loop chains are manufactured to withstand high working loads under abrasive conditions. The simple design makes it easy to repair and assemble or disassemble. Additionally, when one side of the chain has worn down you can flip it to the other side for increased service life. Our rivetless chains are manufactured using high-quality steel alloys and are heat-treated for superior strength and long-term durability.

S-Type Bar Loop Chains

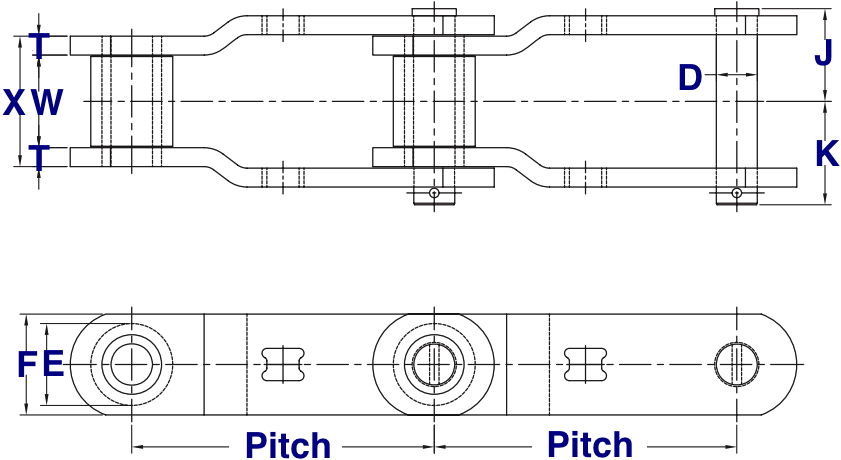

Auxilary cane carrier chains are Engineer Class steel conveyor roller chains that are manufactured from select grades of steel alloys. Our conveyor chains are precision machined and heat-treated for maximum strength and working life. Each component goes through specific heat-treatments to ensure they perform within the chain to their fullest capabilities. The pins and rivets are induction hardened while the bushings and rollers are case-hardened to achieve the maximum hardness on these wear surfaces. Pins and bushings are also made to specific tolerances that generate a specific interference fit to prevent premature wear.

Auxilary Cane Carrier Chain Sizes

K1/ K2 Attachments

Main cane carrier chains are manufactured with M14 attachments every pitch that supports a 5" to 6" roller, the rollers run on rails that increases the overall working life of the chain and reduces the coefficient of friction. Most of these chains are made with a 12" pitch to reduce the number of strands needed, which also reduces the energy and power consumption needed to operate the carrier conveyor. The rollers, bushings, and chain are manufactured from select grades of high-quality alloy steel to increase the chains working load and ability to take shock loads. We can supply the replacement chain and rollers, or complete

pan conveyor assemblies.

Main Cane Carrier Chain Sizes

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit,

sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad

minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea

commodo consequat.

|

|