IEEE841 Severe Duty Motors

Our IEEE841 severe-duty motors are designed for the most rugged and demanding electric motor applications worldwide. These top-of-the-line motors come with an industry-leading 60-month warranty and standard features that ensure impeccable performance and extended motor life. Our severe-duty motors are versatile and reliable, with a lineup that spans from 1HP to 300HP and options for 3600, 1800, or 1200 RPM with a rigid base or c-face configuration. For more detailed information, applications, and features, see below. And if you're ready to invest in our premium motors, our customer service team is here to provide a quote and assist you every step of the way!

Severe Duty Motor Applications

Severe-duty motors are, in essence, the heavier-duty and higher-quality counterparts of standard TEFC motors. They provide clients with more capabilities and longer operating hours and are utilized in the most rugged applications.

Common Applications for Severe Duty Motors Inclue:

- Cooling Towers and Moist or Abrasive Environments

- Rock Crushers and Crushing Equipment

- Low Temperature and High Temperature Applications Ranging From -77F to +104F

- Petroleum and Chemical Industries

- Demanding Industrial Processing Applications

- Wastewater, Paper, Mining, Cement, Automotive, and More

IEEE841 Severe Duty Motor Features

Our severe duty motors stand outside of the norm with unique features for improved reliability, performance, and duty! See the below features for detailed information on what really makes these motors stand out from the rest!

Special Seals

Labyrinth seals on both ends of motor for greater protection of internal bearings and seals.

Arc Arrestor

Unique internal shaft grounding mechanism that protects motor bearings and other components from stray electrical current.

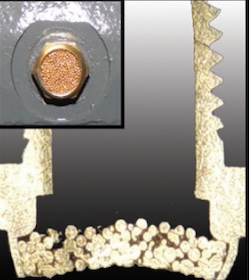

Brass Breathers

Sintered brass breathers allow condensation to leave motor but resist water intrusion.

Pressure Reliefs

Grease pressure reliefs act to battle over-greasing.

Improved Lead Wires

Class H - Silicone Lead wires with Fiberglass jacket protects leads from abrasion but remain flexible

|

|

What is a Severe Duty Motor?

Severe-duty electric motors, unlike their standard-duty counterparts, are robust and heavy-duty drop-ins. They are designed to excel in harsh applications and environments, offering exceptional performance and a long lifespan. What sets them apart is their superior construction and unique features that provide protection against contamination, moisture, vibration, and demanding duty cycles.

How are Severe Duty Motors Different?

See the table below for an easy comparison of severe-duty and standard electric motors. There are additional differences, but these are industry-standard differences.

IEEE841 Severe Duty Motor Cost

IEEE841 motors typically have a higher upfront cost than their standard counterparts (roughly 6%—9% across industry data), but the total cost of ownership has the potential to be reduced due to lower energy consumption, reduced downtime and repairs, safety factors, and more. It is important to note that regardless of the motor, specifications, ratings, and features, it is imperative to maintain the unit properly throughout its lifespan.

What Does IEEE841 mean?

In 1986, the Institute of Electrical and Electronic Engineers (IEEE) developed the 841 Standard for electric motors, primarily for the petroleum and chemical industries. The IEEE841 standard, in essence, improved the reliability, efficiency, and performance rating of motors, making them capable of operating in applications that created a high level of mechanical stress on electric motors and within contaminated environments containing dust, dirt, and liquids that would typically cause premature catastrophic failure to regular-duty motors. IEEE841 includes components such as cast iron frames, stainless nameplates, special bearings, special seals, flatness of feet, non-sparking fan, anti-corrosive painting, and a minimum Class F insulation system. The standard also specifies limits on vibration and noise, a minimum of IP55 protection, premium efficiency, and NEMA Standard sizes. Additionally, severe-duty IEEE841 motors must be capable of operating in conditions ranging from -25°C to +40°F, a maximum altitude of 1,000 meters, humid environments, corrosive circumstances, and salty applications; full voltage starting and Class I Division II hazardous locations. Furthermore, these motors must include a five-year warranty. Any electric motor rated IEEE841 must meet the below key specifications per the most recent update as of May 28th, 2021:

IEEE841 is quickly becoming the standard motor rating preference across many industries; therefore, these motors have become increasingly popular worldwide in the industrial, automotive, and chemical industries. Contact USA Roller Chain today for your severe-duty motor needs!

|

|

|