Premier Series Premium Roller Chains

Premier Series roller chains are a top-of-the-line tier-one class of premium roller chains that offer unmatched roller chain performance, strength specifications, and features that are only found among the best quality roller chains in the world. Utilizing top-end advanced engineering and premium steel alloys these chains are designed and made to last in even the most rugged of applications. We stock a full lineup of ANSI and ISO British Standard sizes of premier roller chains.

Premium Roller Chain Video

Premium Roller Chain FeaturesSeparating itself from the rest and exemplifying features that truly stand out is the name of the game with our selection of Premier Series premium roller chains. The below features display and dive into the technical through mechanical reasoning as to why these chains are becoming an industry favorite.

Premium Roller Chain Sizes

The below charts show the standard sizes and technical data on the Premier Series roller chains, we also supply custom made roller chains and problem solver chains.

ANSI Single Strand Premium Roller Chains

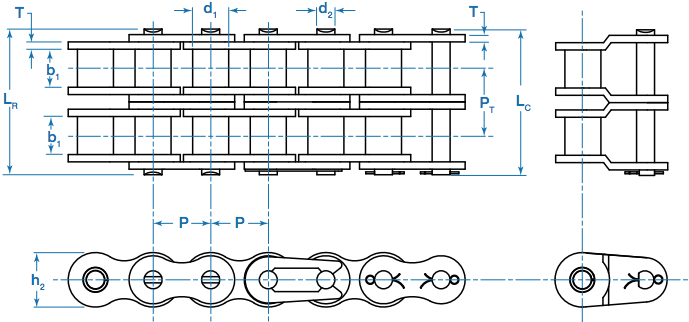

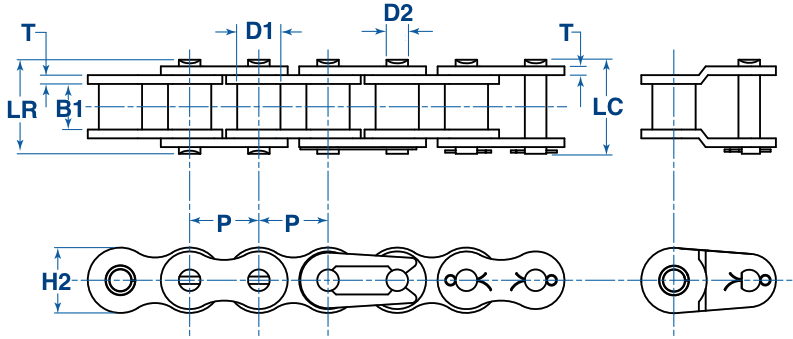

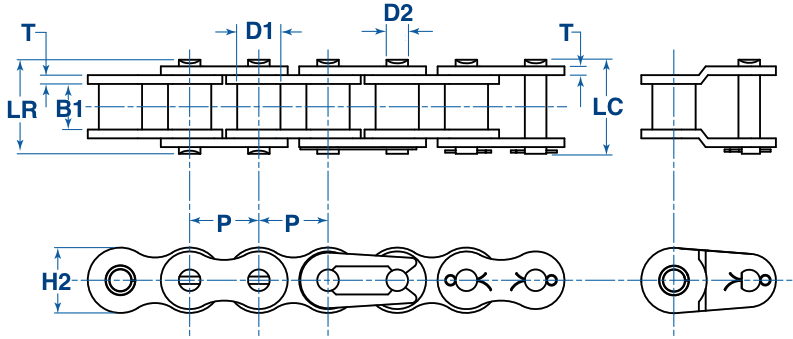

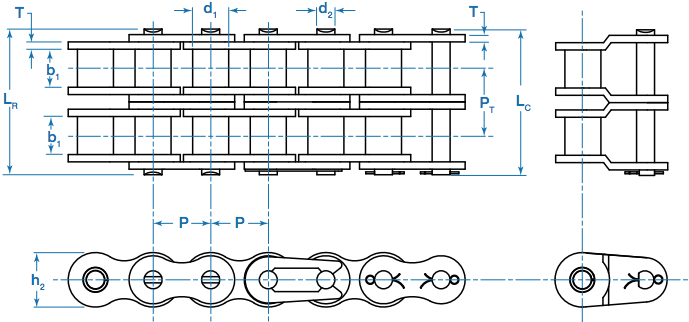

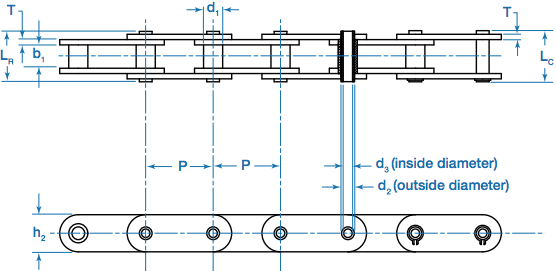

ANSI Double Strand Premium Roller Chains

ANSI Triple Strand Premium Roller Chains

ANSI Four Strand Premium Roller Chains

ANSI Five Strand Premium Roller Chains

ANSI Six Strand Premium Roller Chains

ANSI Cottered Premium Roller Chains

Cottered roller chain is manufactured utilizing cotter keys instead of rivets for keeping the chain assembled. The benefit of this is that it is easier to disassemble the chain for making repairs or edits.

ANSI Heavy Premium Roller Chains

Heavy roller chains are manufactured dimensionally the same as standard chains, with the important exception of the side plates. Heavy-duty chains utilize a thicker side plate, which in turn creates a chain with higher capacities and working loads while also increasing fatigue resistance and shock load absorption.

Riveted Heavy Roller Chains

Cottered Heavy Roller Chains

Premium Stainless Steel Roller Chains

When corrosion resistance, abrasion resistance, or FDA requirements need to be met, stainless steel roller chains are a must. We supply Premier Series premium stainless steel roller chains in simplex (singe-strand) and duplex (double-strand) configurations in 304, 306, or even 600-series stainless steel options. Remarkably, stainless steel roller chains offer the highest resistance to corrosion and abrasion out of any other roller chain and can operate in extremely high or low-temperature applications.

Simplex 304-Grade Stainless Steel Roller Chains

Duplex 304-Grade Stainless Steel Roller Chains

Premium 316-Grade Stainless Steel Roller Chain316-Grade stainless steel roller chains show superior results in chemical attack resistance and weldability and are often referred to as non-magnetic due to the material's minimal magnetic effects.

High-Strength 600-Series Stainless Chains

600-Series stainless steel roller chains offer optimal strength and shock-load bearing capabilities out of any other grade. It utilizes special heat-treated stainless steel parts to increase the working capacity of the chain.

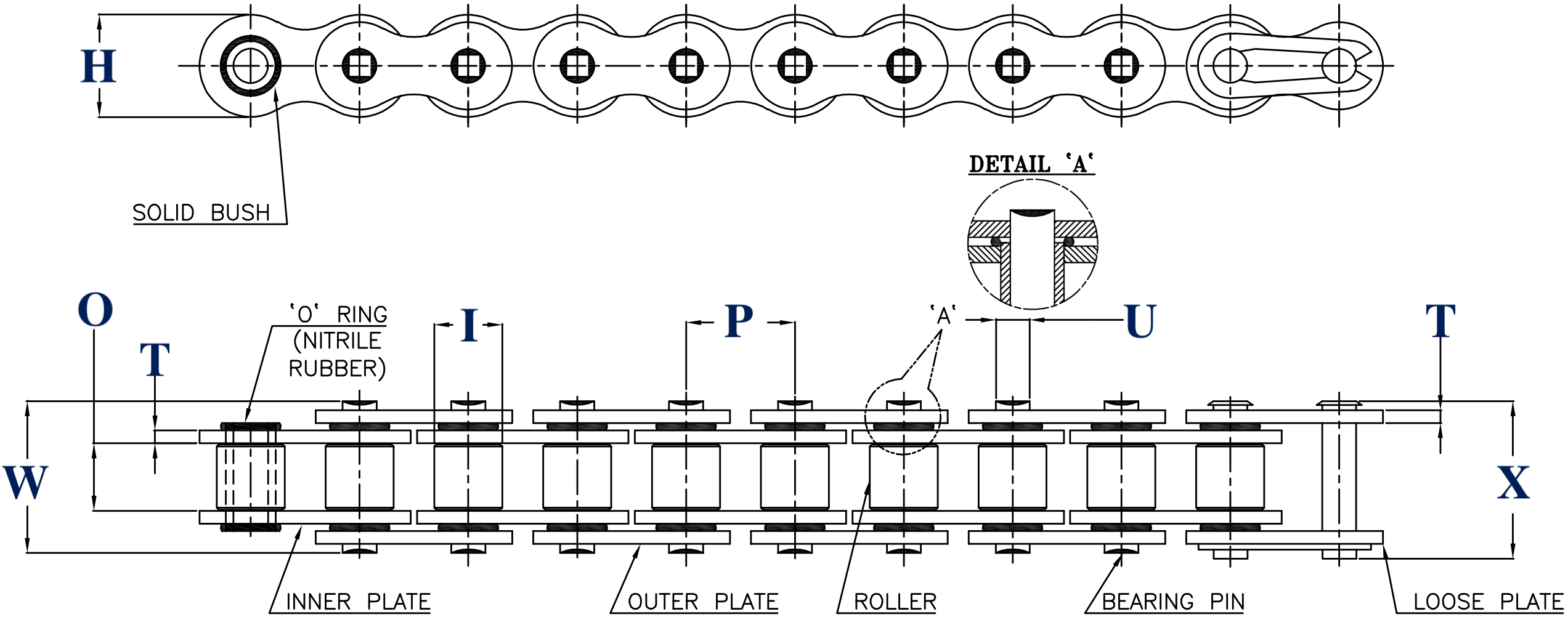

Premium Hollow Pin Roller Chains

Hollow pin chain is manufactured in a way that allows for attaching items to the chain through the "hollow Pins". It is also used in numerous elevating, conveying, and bucket applications. We offer one of the largest selections of Hollow Pin chains on the market ranging from standard steel to stainless steel.

Standard Hollow Pin Chain

Standard Stainless Steel Hollow Pin Chain

Double Pitch Hollow Pin Chain

Stainless Steel Double Pitch Hollow Pin Chain

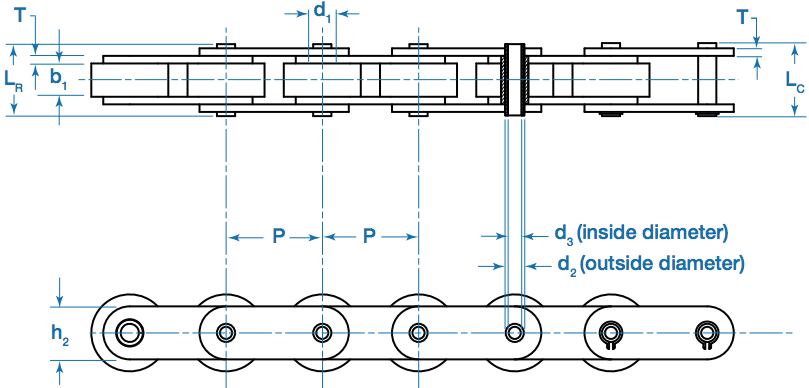

Premium Side Bow Roller Chains

Side bow chains are also commonly referred to as side-flex or side-flexing roller chains due to their ability to flex around turns while in operation.

Standard Side Bow Roller Chains

Stainless Steel Side Bow Chains

Double-Pitch Side Bow Roller Chains

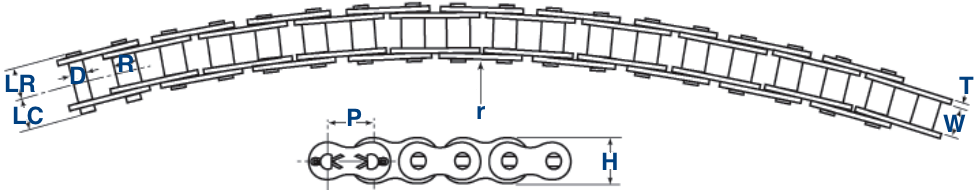

Premium O-Ring Roller Chains

O-ring roller chains utilize rubber o-rings that are placed between the inner and outer link plates. This chain type keeps dirt, dust, or other unwanted contents from getting into the internal bearing surfaces of the chain while also keeping the factory-supplied lubricant within the internal parts of the roller chain. This design has up to a 10X longer working life factor in certain applications and is lubed for life, making it a good candidate for hard-to-reach or dangerous chain lubricating applications.

Metric Roller Chains

Premier Series metric roller chains are manufactured in accordance with ISO 606B, BS 228 British Standards, and DIN 8187 German Standards.

Premium Double Pitch Roller ChainsDouble-pitch roller chains are dimensionally identical to standard roller chains with the exception of the pitch. For example, C2080H has a 2" pitch, which is double that of the (1" pitch) chain. These chains are used in a wide range of conveying applications.

Standard Double Pitch Chains

Oversized Roller Double Pitch Chains

Type A Double Pitch Chains

|

|

|